EEC USA

Moving Bed Bio Reactors

PACKAGE PLANTS FOR DOMESTIC AND INDUSTRIAL WASTEWATER

Moving Bed Bio Reactors (MBBR) biologically treat wastewater by circulating moving media in aerobic and anaerobic activated environments. The plastic media used has a specific gravity less than 1.0. The large surface area of the plastics provide abundant surface for bacterial growth. Biomass grows on the surface as a thin film. Increased levels of the biofilm enhance the biological treatment process by introducing a more robust microbial community to break down nutrients.

Moving Bed Bio Reactor (MBBR)

The Moving Bed Bio Reactor (MBBR) process is a state-of-the-art fixed-film (or attached growth) biological process used for wastewater treatment both municipally and industrially for BOD removal, nitrification, and denitrification. MBBR systems are an ideal treatment solution for high-strength wastewater, siting applications requiring a compact physical footprint, and applications that lack the resources for a full time licensed operator.

Advantages

- Efficient

- Shock resistant

- Bio media allows for much higher effective treatment than with traditional activated sludge systems

- Wide variety of applications

- Compact – small footprint

- Can treat a wide range of flows in a small area

- Low odor

- Low power requirements

- Easy to operate

EEC Wastewater Systems

- Packaged Moving Bed Bio Reactors (MBBR)

- Designed to treat 5,000 to 120,000 gallons per day in single units, higher flows in modular, parallel operation

- Quick start-up

- Fully automatic with minimal waste

- Designs available to meet all standard regulatory effluent requirements

- Customizable to meet specialized treatment objectives

- Delivered ready to operate - require only influent, effluent, and power connections for full system start-up.

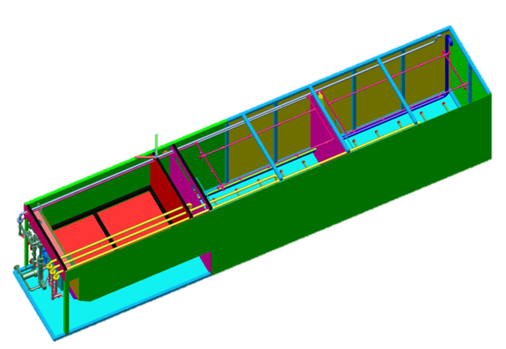

sample CON6 configuration

Modular, Packaged WWTP

- EEC Bio units are easy to transport, relocate, and expand

- Optional integrated housing, no additional cover needed

- Built or transported in standard ISO freight containers

Standard MBBR Models

MBBR system design is determined primarily by flow and targeted contaminants in the water system.

- Other contaminants can be treated with additional processes or modified systems

- Custom systems can achieve higher flows than listed for same footprint

- Nitrification & De-Nitrification are standard depending on model

- Smaller units available

AMB Bio Media

Media is the key to effective MBBR treatment.

- MBBR loaded with AMB Bio Media

- AMB Bio Media provides 950 m2/m3 Surface Area inside Waste Water Treatment Plants (WWTP)

- Provides Large Quantity of Bio Mass for High-Efficiency and Shock-Resistant System

- Clog Free Operation

- No Backwash, Minimum Service Requirements, and Minimal Waste for Normal Operation

- Consistently Meet Stringent Effluent Standards in Smaller Footprint Systems

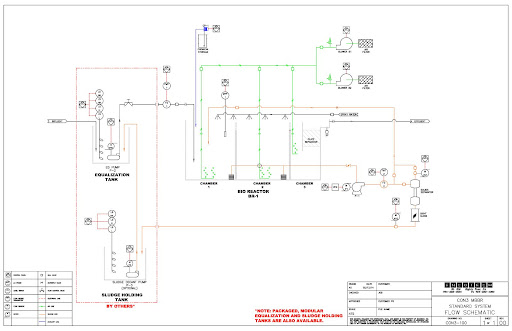

EEC USA Basic Process

EEC USA Basic Process

Basic Process & Results

Raw Wastewater

EQ Tank

Post MBBR, No Filtration

Typical Clients and Applications

- Domestic Wastewater – Up to 2000 people

- Shopping Centers

- Camps, Military, Schools & Universities

- Condominiums & Housing Developments

- Hospitals

- Remote Locations & Islands

- Industrial Wastewater

- Farming & Agricultural

A Deep Dive into the Technology Behind Moving Bed Bio Reactors (MBBR)

Moving Bed Bio Reactors (MBBR) biologically treat wastewater by circulating moving media in aerobic and anaerobic activated sludge environments. This plastic (usually HDPE, polyethylene or polypropylene) media has specific gravity less than 1.0. The large surface area of the plastics provide abundant surface for bacterial growth. Biomass grows on the surface as a thin film whose thickness usually varies between 50-300 microns. Increased levels of biofilm enhance the biological treatment process by introducing a more robust microbial community to break down nutrients.

Medium or coarse bubble diffusers uniformly placed at the bottom of the reactor maintains a dissolved oxygen (DO) concentration of > 2.5-3 mg/L for BOD removal. Higher DO concentrations are typically maintained for nitrification. To retain the media flowing out of the tank, screens are placed on the downstream walls. A clarifier is sometimes placed downstream of the MBBR tank to separate the biomass and the solids from the wastewater.

For denitrification, anoxic and anaerobic MBBR tanks are used. The anoxic tank is similar to the aerobic tanks described above, except that no oxygen is supplied and mixers are usually required to agitate the media and wastewater solution; the tank contains no diffusers. Other features, such as the screens, are the same as the aerobic reactors, although the design may be slightly different.

Wastewater enters the MBBR where the biomass attached to the surface of the media degrades organic matter resulting in BOD removal and/or nitrification depending on the type and characteristic of the wastewater. As described in the previous sections, organic carbon is converted to carbon dioxide and leaves the system while the ammonia and nitrogen in the organics are converted to nitrates through the nitrification process. Oxygen required for the process is provided through the diffusers installed at the bottom of the reactors. The treated wastewater then flows through the screens to the downstream clarifier where the biomass and solids are separated from the wastewater.

In the MBBR technology the biofilm grows and is protected within engineered plastic carriers, which are carefully designed with high surface area. This allows the biological reactions to be carried out in a controlled environment. These specially designed plastic biofilm carriers are suspended and in continuous movement within a tank or reactor of specified volume. The dissolved oxygen needed to synthesize the organic matter is supplied by air blowers in the form of coarse bubbles. Oxygen dissolved in the waste water may be used by the bacteria for carbon ingestion and growth. The bacteria grow on the plastic media by using the organic content in the raw sewage and the dissolved oxygen available. Due to constant aeration the media is set in motion, so that continuous mixing takes place. The bacterial layer growth on the media surface increases to a certain extent, and then gets agitated off after a specific period. This phenomenon is called sloughing. This creates new surface for further bacterial growth. Sloughing takes place only after complete growth and subsequent dying of the bacterial layer. The sloughed bio mass can then be removed for dewatering or return to the head of the system.